Battery plant key to Ford EV affordability reportedly set for Michigan

Ford is reportedly partnering with the world’s largest supplier of EV battery cells, China’s CATL, for a plant in Michigan that will produce them for upcoming Ford electric vehicles, according to Friday afternoon reports from the Detroit News and Bloomberg.

Outside of Ford’s $11.4 billion electric truck manufacturing complexes in Tennessee and Kentucky and its BlueOvalSK venture with South Korea’s SK On, the reportedly chosen site around Marshall, Michigan, may prove to be the most important industrial operation yet as the automaker seeks greater profitability from its EVs.

BlueOvalSK Battery Park – rendering, September 2021

According to the Detroit News report, the project may create roughly 2,500 jobs and draw at least a $2.5 billion investment. Under an arrangement that appears to deviate from existing joint ventures, Ford would own the land and plant, manage the workforce, and receive any state incentives.

The facility will reportedly make lithium-iron-phosphate (LFP) batteries, which tend to be cheaper. Due to a more stable supply of the critical materials they need, the materials that go into them are less subject to price volatility. But the tradeoff has been that these cells are somewhat heavier for the amount of energy they store, and cold-weather charging can slow dramatically.

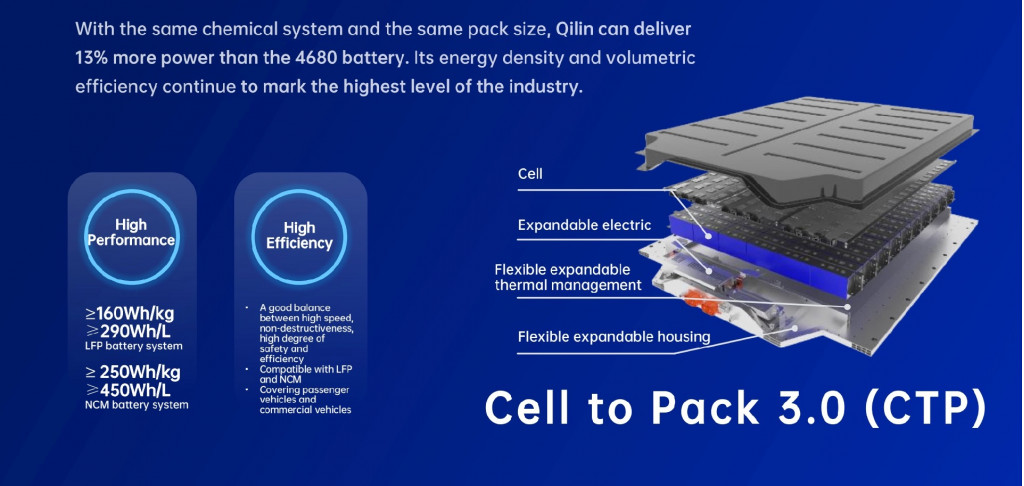

CATL third-generation cell-to-pack tech

These may no longer be such disadvantages by the time the vehicles reach market. CATL has already shown LFP cells, in combination with its latest cell-to-pack technology, can achieve energy densities close to that of current lithium-ion battery packs.

Ford said last year that LFP batteries are bound for the Mustang Mach-E, Ford F-150 Lightning, and perhaps other products, as they ramp up, perhaps allowing Ford to cut prices due to a pending EV price war and/or achieve greater profitability.

2022 Ford F-150 Lightning

CEO Jim Farley said last week that Ford’s future EVs will be “radically simplified,” as it seeks to use the smallest possible battery packs, minimize parts, and streamline the assembly process for upcoming EVs.

According to the reports, an announcement on the facility is due Monday.

Electric cars news.